At YALIS, with over 16 years of experience in manufacturing high-quality door locks, door handles, and hardware, we prioritize the reliability and durability of our products. One of the key tests we use to ensure the longevity of our door handles is salt spray testing. This process simulates harsh environmental conditions, allowing us to assess how our door handles will perform over time, especially in coastal or humid regions where corrosion is a significant concern.

What is Salt Spray Testing?

Salt spray testing, also known as salt fog testing, is a controlled process that exposes materials to a fine mist of saltwater in a testing chamber. The goal is to accelerate the natural corrosion process, simulating how a product would behave when exposed to salty or humid environments. This test is essential for ensuring that door handles can withstand the damaging effects of corrosion and maintain their appearance and functionality over time.

How Does Salt Spray Testing Work?

The salt spray test is carried out in a specially designed chamber, where a fine mist of saltwater (usually a sodium chloride solution) is sprayed onto the door handle. The chamber is maintained at specific temperature and humidity levels to mimic real-world conditions, particularly those found in coastal areas or regions with high humidity.

Here’s a breakdown of how the process works:

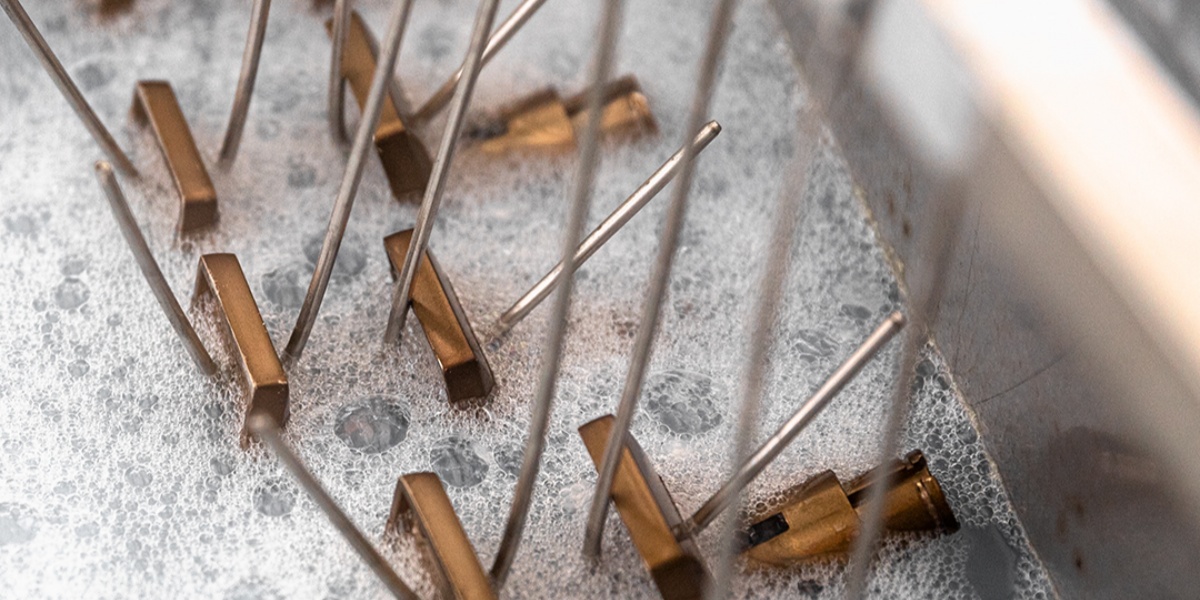

Preparation of the Door Handle: Before testing, the door handles are thoroughly cleaned to remove any surface contaminants. This ensures that the test results reflect the handle’s true resistance to corrosion.

Exposure to Salt Mist: The cleaned door handles are then placed inside the salt spray chamber. The chamber continuously sprays a fine mist of saltwater onto the handles, creating an accelerated corrosion environment.

Test Duration: The test duration can vary depending on the standards being tested. Typically, the process can last anywhere from 24 hours to several days. Longer exposure times simulate prolonged exposure to harsh environmental conditions, giving us a clear picture of how the door handle will perform in the real world.

Inspection and Evaluation: After the test is completed, the door handles are inspected for any signs of corrosion, discoloration, or degradation. If the handles show significant damage, adjustments to materials or coatings can be made to improve their performance.

Why is Salt Spray Testing Important for Door Handles?

1. Ensuring Durability

Salt spray testing plays a vital role in determining the long-term durability of door handles. It helps ensure that our door handles will not corrode or degrade when exposed to salt or moisture, which is especially important for installations in coastal or high-humidity areas.

2. Meeting Industry Standards

For a door handle to be considered reliable and safe, it must meet various industry standards. Salt spray testing helps YALIS ensure that our products comply with these standards, guaranteeing our customers that our door handles are of the highest quality.

3. Prolonging Product Lifespan

By testing our door handles under accelerated conditions, we can predict their lifespan more accurately. Handles that pass salt spray testing are less likely to rust or deteriorate, which extends the product's life and ensures it continues to perform effectively for years to come.

4. Quality Assurance

At YALIS, we take pride in delivering high-quality door handles that customers can trust. Salt spray testing is an essential part of our quality assurance process, ensuring that every product meets our strict durability requirements.

The Benefits of Salt Spray Testing for Door Handles

Salt spray testing is not only about corrosion resistance but also about improving overall product quality. By identifying potential weak points in materials or coatings early in the manufacturing process, YALIS can refine our products and provide customers with superior door hardware that stands the test of time. Here are some key benefits of salt spray testing:

- Increased Customer Confidence: Customers can trust that YALIS door handles are rigorously tested and proven to perform well in a variety of environmental conditions, from dry to highly humid or coastal areas.

- Reduced Maintenance Costs: Door handles that pass salt spray testing are less prone to rust and corrosion, reducing the need for repairs or replacements over time.

- Better Performance in Challenging Environments: Whether it’s a beachside home or a high-humidity office, YALIS door handles will perform reliably, maintaining their appearance and functionality.

At YALIS, we are committed to providing top-quality door handles and hardware that deliver exceptional performance and durability. Salt spray testing is a critical part of our rigorous quality control process, ensuring that every door handle we produce can withstand the harshest environments. By exposing our products to salt mist and simulating the effects of corrosion, we ensure that YALIS door handles meet the highest standards for quality, reliability, and longevity.

Salt spray testing not only helps us maintain the highest level of product quality, but it also gives our customers peace of mind, knowing that their door handles will last, even in the most challenging conditions.

Post time: Dec-03-2024