YALIS, with 16 years of expertise in door lock manufacturing, is committed to producing high-quality door hardware components. One of the key factors that contribute to the durability and aesthetics of door handles is the surface treatment. This article explores various surface treatment techniques and compares their wear resistance, ensuring that you select the most suitable option for your needs.

Common Surface Treatment Techniques

Electroplating

Electroplating is a popular technique where a metal coating is deposited onto the surface of the door handle using an electric current. This method enhances the handle’s appearance and provides a protective layer against corrosion. Common finishes achieved through electroplating include chrome, nickel, and brass. Electroplated finishes are known for their smoothness and reflective quality, making them a favored choice for modern and classic designs.

Powder Coating

Powder coating involves applying a dry powder to the door handle’s surface, which is then cured under heat to form a durable finish. This method provides a thick, uniform coating that is resistant to chipping, scratching, and fading. Powder-coated handles are available in a variety of colors and textures, making them suitable for both contemporary and industrial-style interiors.

thick, uniform coating that is resistant to chipping, scratching, and fading. Powder-coated handles are available in a variety of colors and textures, making them suitable for both contemporary and industrial-style interiors.

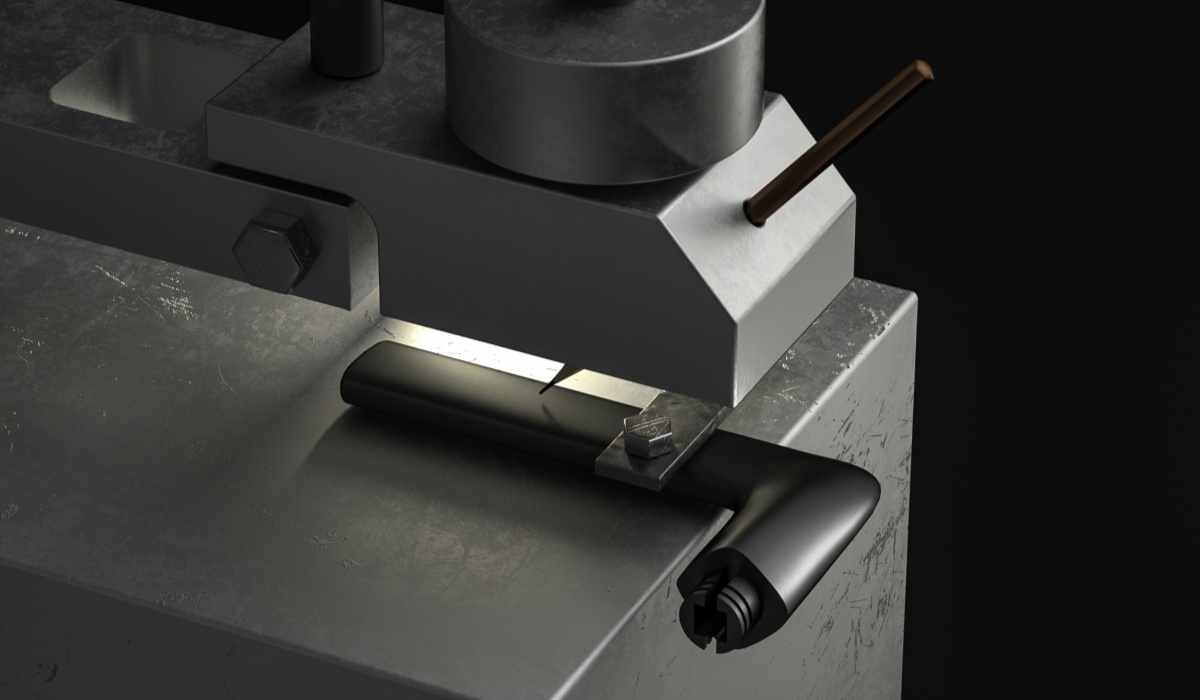

PVD (Physical Vapor Deposition)

PVD is an advanced surface treatment technique that involves the deposition of a thin, hard coating onto the door handle in a vacuum environment. This process results in a finish that is highly resistant to wear, corrosion, and tarnishing. PVD finishes are often used for high-end door handles due to their superior durability and luxurious appearance. Common PVD finishes include gold, black, and rose gold.

Anodizing

Anodizing is a process used primarily on aluminum door handles, where the surface is treated with an electrolytic passivation process to increase its thickness and resistance to wear. This method also allows for coloring the metal, offering a wide range of vibrant and long-lasting finishes.

Comparing Wear Resistance

Electroplating

While electroplating provides excellent corrosion resistance, its wear resistance can vary depending on the thickness of the coating. Over time, electroplated surfaces may show signs of wear, especially in high-traffic areas.

Powder Coating

Powder-coated finishes are highly durable and resistant to wear, making them ideal for environments where the door handles are subject to frequent use. However, if the coating is damaged, it can be difficult to repair.

PVD Coating

PVD coatings are among the most wear-resistant surface treatments available. They maintain their finish even under heavy use and are resistant to scratches, making them a premium choice for long-term durability.

Anodizing

Anodized finishes are highly wear-resistant and are particularly effective in preventing corrosion. However, they may not offer the same level of aesthetic variety as electroplating or PVD.

When selecting a door handle, considering the surface treatment technique is crucial for ensuring long-lasting performance and maintaining the aesthetic appeal of your interiors. At YALIS, we offer a range of surface-treated door handles, each designed to meet different needs and preferences. Whether you prioritize wear resistance, appearance, or both, our products are crafted to deliver superior quality and durability.

Post time: Sep-04-2024